Copper Nickel Plate and A193 Grade B7 Bolts: A Powerful Duo for Corrosion Resistance and Strength

In various industrial applications, especially those involving marine environments and offshore structures, the challenge of corrosion resistance is paramount. The constant exposure to saltwater and harsh conditions can lead to significant damage and maintenance costs if the right materials aren’t used. Copper Nickel plates and A193 Grade B7 bolts have emerged as a powerful duo, combining the benefits of both materials to address this challenge effectively.

Understanding Copper Nickel Plate:

Copper Nickel is an alloy that primarily consists of copper (Cu) with a small percentage of nickel (Ni). The most commonly used grade is CuNi 90/10 (90% copper and 10% nickel). Other grades, such as CuNi 70/30, are also available. This alloy offers exceptional corrosion resistance, especially in marine environments, making it an ideal choice for applications like shipbuilding, offshore platforms, desalination plants, and various marine components.

The Key Advantages of Copper Nickel Plate:

Corrosion Resistance: Copper nickel plate composition provides inherent resistance to seawater corrosion, biofouling, and stress corrosion cracking. This extends the lifespan of the components and reduces maintenance costs significantly.

Antimicrobial Properties: Copper Nickel exhibits antimicrobial properties, which make it suitable for applications in healthcare facilities and environments where controlling microbial growth is crucial.

Low Macrodensity: Copper Nickel has a lower macrodensity compared to steel, which means it is less prone to biofouling, reducing the need for frequent cleaning and maintenance.

Thermal Stability: This alloy maintains its mechanical properties even at elevated temperatures, making it suitable for applications involving high-temperature seawater.

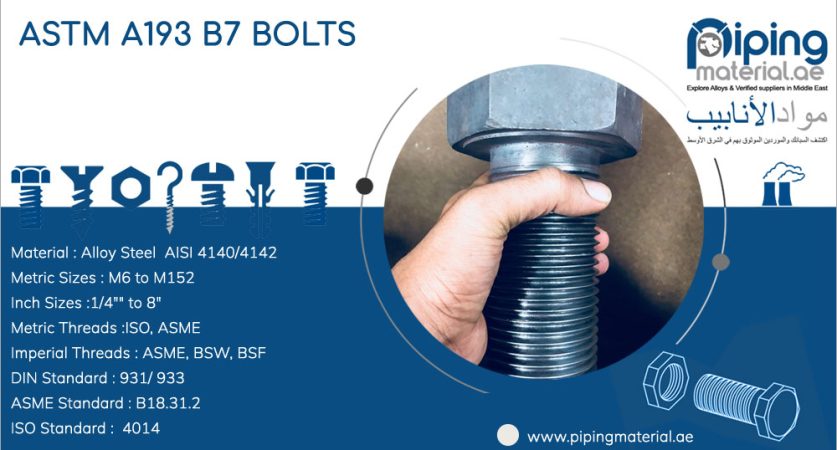

A193 Grade B7 Bolts:

A193 Grade B7 is a high-strength steel bolt material typically used in high-temperature and high-pressure applications. These bolts are heat-treated chromium-molybdenum alloy steel fasteners, conforming to ASTM A193 standard specifications. They are commonly used in industries like oil and gas, petrochemical, and power generation, where elevated temperatures and mechanical stresses are prevalent.

The Key Advantages of A193 Grade B7 Bolts:

Strength and Toughness: A193 Grade B7 bolts offer excellent tensile strength and toughness, providing a secure and reliable fastening solution for critical applications.

High-Temperature Performance: These bolts retain their mechanical properties at higher temperatures, making them suitable for use in high-temperature environments such as steam systems.

Corrosion Resistance: While A193 Grade B7 bolts are not inherently corrosion resistant like Copper Nickel, their application alongside Copper Nickel plates can enhance overall corrosion protection, ensuring the longevity of the assembled components.

Wide Application Range: A193 Grade B7 bolts come in various sizes and configurations, making them suitable for a broad range of industrial applications.

The Power Duo:

Combining Copper Nickel plates with A193 Grade B7 bolts results in a highly effective and durable solution for applications requiring both corrosion resistance and mechanical strength. When these materials are used together, they complement each other’s strengths and mitigate weaknesses, offering unparalleled performance in challenging environments.

Applications:

The Copper Nickel plate and A193 Grade B7 bolt combination find numerous applications, including:

Shipbuilding and Marine Equipment: For hulls, offshore platforms, heat exchangers, and underwater components.

Desalination Plants: For condensers, heat exchangers, and piping systems.

Oil and Gas Industry: For offshore rigs, pipelines, and subsea equipment.

Power Generation: For steam systems and cooling applications.

Conclusion:

Copper Nickel plates and A193 Grade B7 bolts have proven to be a powerful duo in the fight against corrosion and mechanical stress in various industrial applications. Combining the exceptional corrosion resistance of Copper Nickel with the strength and toughness of A193 Grade B7 bolts results in a long-lasting and reliable solution, reducing maintenance costs and ensuring the integrity of critical components in harsh environments. When selecting materials for projects in marine and high-temperature applications, considering the synergistic benefits of this duo can be a wise choice for improved performance and peace of mind.

Ashmawi Sami has a Bachelor degree in Travel and Tourism Management from the University of Minnesota. He has his own travel vlogging channel. Besides being a fantastic yoga instructor he has travelled to 9 countries and planning his next trip soon. As the father of 3 dogs, he is well-trained in parenting, crowd control, and crisis situations.

ABOUT ME

Gillian is a freelance blogger, student, and full-time traveler. Each day she spends her time exploring something exciting to help people find the information they need while travelling to a new destination. Whether it be the place to enjoy holidays, or a spot to throw a party or hidden gems that you must visit in the city.

ALL CATEGORIES

- Adventure (13)

- Automotive (8)

- blog (8)

- Business (682)

- Education (13)

- Event (4)

- Health (285)

- Insurance (11)

- KOKITOTO (1)

- Lifestyle (13)

- News (1)

- Real Estate (21)

- Shopping (27)

- Technology (24)

- Travel (7)

POPULAR POST

January 27, 2021 -

Adventure Travel For The Audacious Spirit

January 27, 2021 -

Small Business Loans for Women

January 27, 2021 -

Adventure Tours in Vanuatu

RECENT POST

November 25, 2024 -

The Ultimate Guide to Engaging in Solar Panel Forums for Effective Discussions and Insights

In the modern world, renewable energy is rapidly...

November 23, 2024 -

Guide To Carbon Steel Pipe Fittings in Industrial Use

Carbon steel pipe fittings are extremely useful in...

November 23, 2024 -

What Are the Advantages of Turning Off Private Browsing? How to Turn Off Private Browsing

Private browsing, also known as incognito mode, is...

November 20, 2024 -

Website Gestalten und Websites Designen: Der Schlüssel zu Ihrer Online-Präsenz

In einer zunehmend digitalisierten Welt ist eine beeindruckende...